The edge bander from Comeva Woodworking Machinery is available in various models within the Junior range, designed to deliver highly efficient edge banding processes with flawless finishes. These edge banders are engineered to enhance productivity by combining ease of adjustment, safety, and advanced technology.

Edge banders junior range: technical features

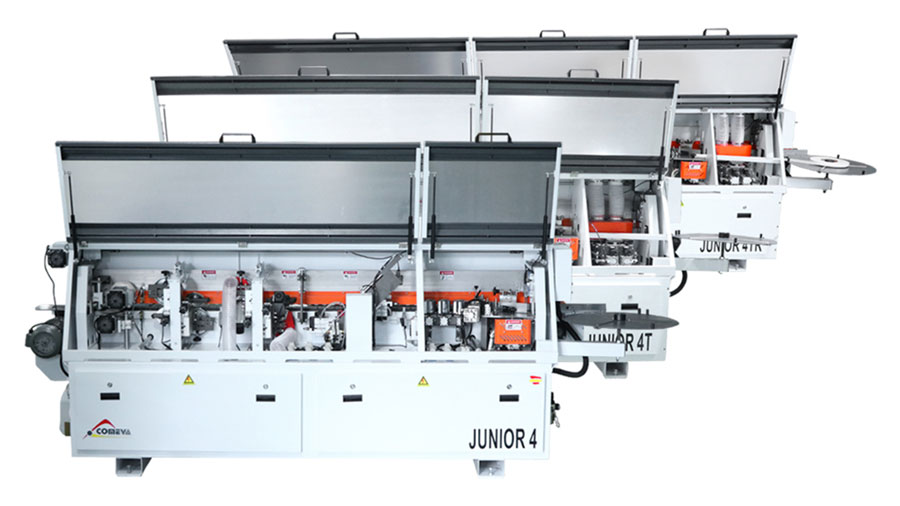

Comeva Woodworking Machinery offers several models within the Junior range (Junior 4, Junior 4T, and Junior 4TR) to meet the diverse production needs of different companies. Below are the key technical features:

- Machine control. The intuitive touchscreen enables easy activation and deactivation of work groups. Its graphical interface is simple and user-friendly. Additionally, it features an automatic digital thermostat to control the adhesive temperature, ensuring an efficient process. The control panel includes a connection selector, a temperature display, and an emergency stop button for enhanced safety.

- Work groups. Tupi Group: two tupi spindles for edge trimming before gluing (available in the 4T and 4TR models). Glue Application Group: 3-liter glue tank with 5 heating elements and a flow regulator. End trimming group: equipped with two high-frequency motors of 0.37 kW. Edge trimming group: Two 0.75 kW motors for edge finishing. Corner rounding group: Two 0.3 kW motors for corner rounding (available in the 4TR model). Scraping group: removes excess adhesive and any undulations from the board. Cleaning device: Sprays cleaning liquid to remove any residual glue. Polishing group: Two independent 0.18 kW motors for edge polishing and cleaning.

- Piece Pressure and Feeding System. These machines feature a piece-feeding system with a motorized drag chain and rubber-coated pads, along with an automatic height-adjustable pressure system. This ensures stable panel movement. Rubberized wheels apply firm pressure to secure the piece for stable operation.

- Piece Entry Stop. A pneumatic safety piston regulates piece entry, reducing intervals between pieces, optimizing production time, and preventing potential malfunctions due to material accumulation.

- Lubrication System. The machines are equipped with either a manual lubrication pump (in the 4 and 4T models) or an automatic pump (in the 4TR model). Both systems are centralized, ensuring efficient lubrication of critical components to prolong the machine’s lifespan.

- Additional Specifications: total power: Junior 4 (6.5 kW), Junior 4T (11 kW), Junior 4TR (11.7 kW). Maximum workpiece thickness: 10 mm to 60 mm. Feed speed: 15–19 m/min. Glue tank heating elements: 5 units. Dimensions: Junior 4 (3450x700x1320 mm), Junior 4T (4000x700x1320 mm), Junior 4TR (5000x700x1320 mm).

Contact us for complete technical details on the Junior range edge banders, get in touch with us. The wood machinery specialists at Comeva will advise you on the best solutions to optimize the performance and profitability of your production line.

Contact us for complete technical details on the Junior range edge banders, get in touch with us. The wood machinery specialists at Comeva will advise you on the best solutions to optimize the performance and profitability of your production line.