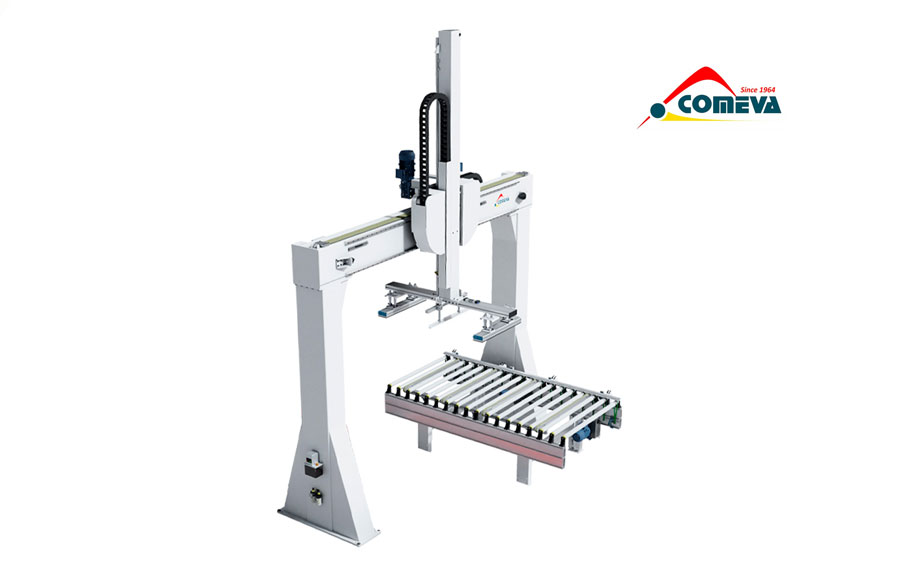

The Comeva Woodworking Machinery loading and unloading bridge is intended for the automation of processes in the production line.

This loading and unloading bridge consists of a two-legged system with a grid equipped with vacuum bars. It allows individual workpieces to be loaded onto the infeed table and unloaded after machining. This ensures a precise, efficient and safe workflow.

It also enables complete automation of the line. Loading and unloading bridges can be incorporated throughout the entire workflow for full automation of the production process.

This line composition allows for the insertion of workpiece packages that are automatically loaded, machined and restacked without any operator intervention. Thus, the Comeva loading and unloading bridge leads to significant savings in production costs.

Automation includes the entire production process, from the entry table to the part exit table. These tables have a centring system by which the parts are placed in the same centred position on the table, so that the loading or unloading bridge picks up the parts and stacks them at the next station, making a perfect stack.

If you want to know the details of Comeva’s loading and unloading bridge, please contact us. Our technical specialists in woodworking machinery will inform you on how to make the transformation to Industry 4.0 to increase the productivity and profitability of your company.